TRANSPORTATION

Aerospace

Technologies That Go Further with Out of This World Performance.

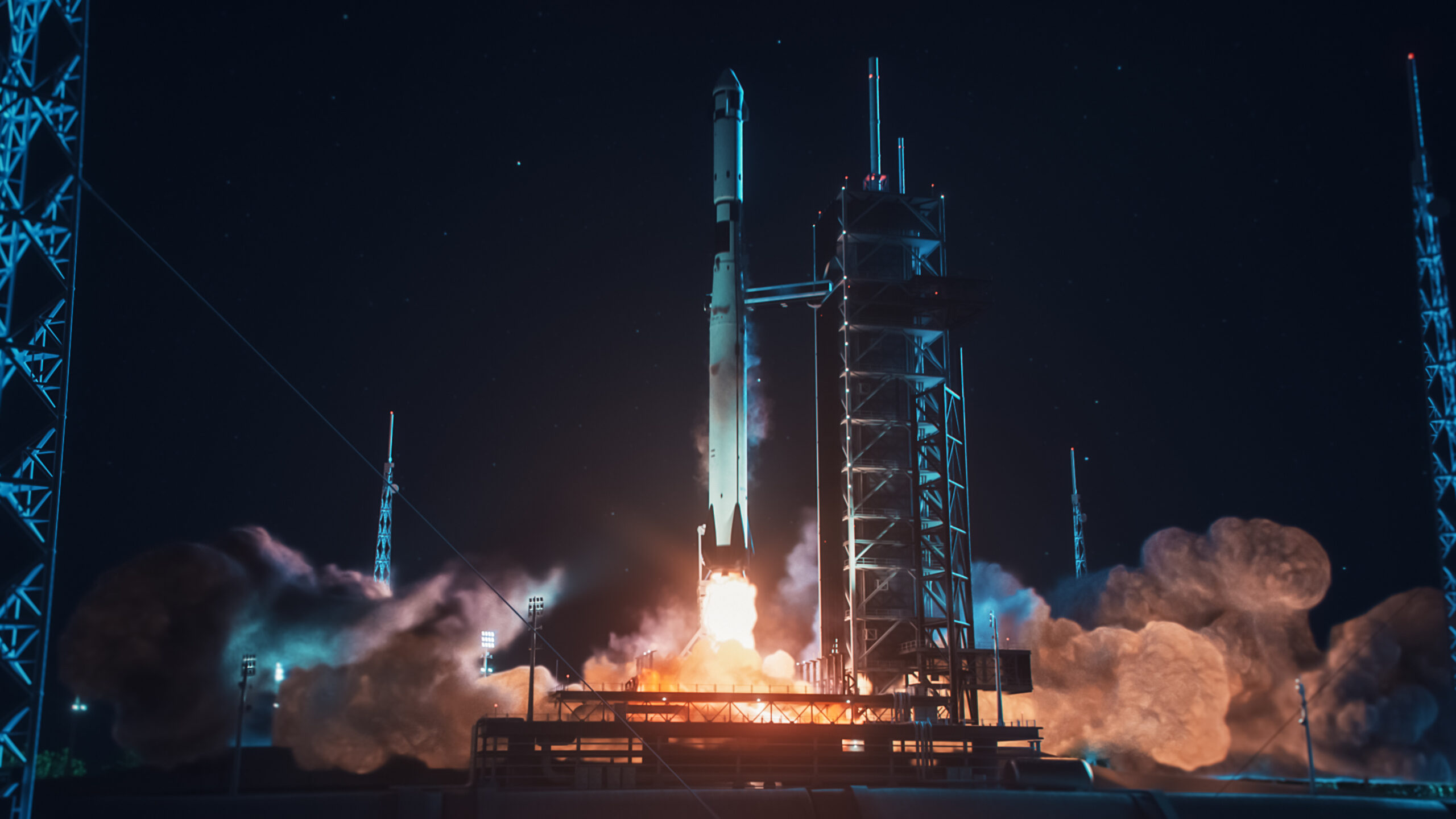

From stratospheric cold at –80 °C to searing re-entry at over 2000 °C, modern aerospace vehicles—commercial airliners, rotorcraft, satellites, reusable spacecraft, and now, the launch infrastructure that supports them—demand materials that safeguard every system, every second. Alkegen leads with engineered filtration, insulation, refractory, and fire barrier technologies built for these extremes, where reliability is measured in milliseconds and safety is non-negotiable.

World Class Insulation & Filtration Media Driving Optimal Aerospace Performance

ALKEGEN HIGH TEMPERATURE INSULATION SOLUTIONS

High Temperature Solutions for the Most Extreme Environments

During space launch, flight, and re-entry, our Saffil®-based heat shields and Fiberfrax® insulation materials defend engine casings and exhausts from burning hot gases, rapid cycling, and foreign object damage. Our advanced high temperature solutions are lightweight, flexible insulation and dielectrics for engine nacelles, exhaust ducts, and payload heat shields, with pure ceramic fiber integrity above 1200 °C-1600 °C.

Applications

- Engine & Aerospace Craft Environment Protection

- Heat Shields

Learn More

During space launch, flight, and re-entry, our Saffil®-based heat shields and Fiberfrax® insulation materials defend engine casings and exhausts from burning hot gases, rapid cycling, and foreign object damage. Our advanced high temperature solutions are lightweight, flexible insulation and dielectrics for engine nacelles, exhaust ducts, and payload heat shields, with pure ceramic fiber integrity above 1200 °C-1600 °C.

Applications

- Engine & Aerospace Craft Environment Protection

- Heat Shields

ALKEGEN CRYOGENIC INSULATION SOLUTIONS

Ultra-Low Temperature Insulation to Prevent Boil-Off

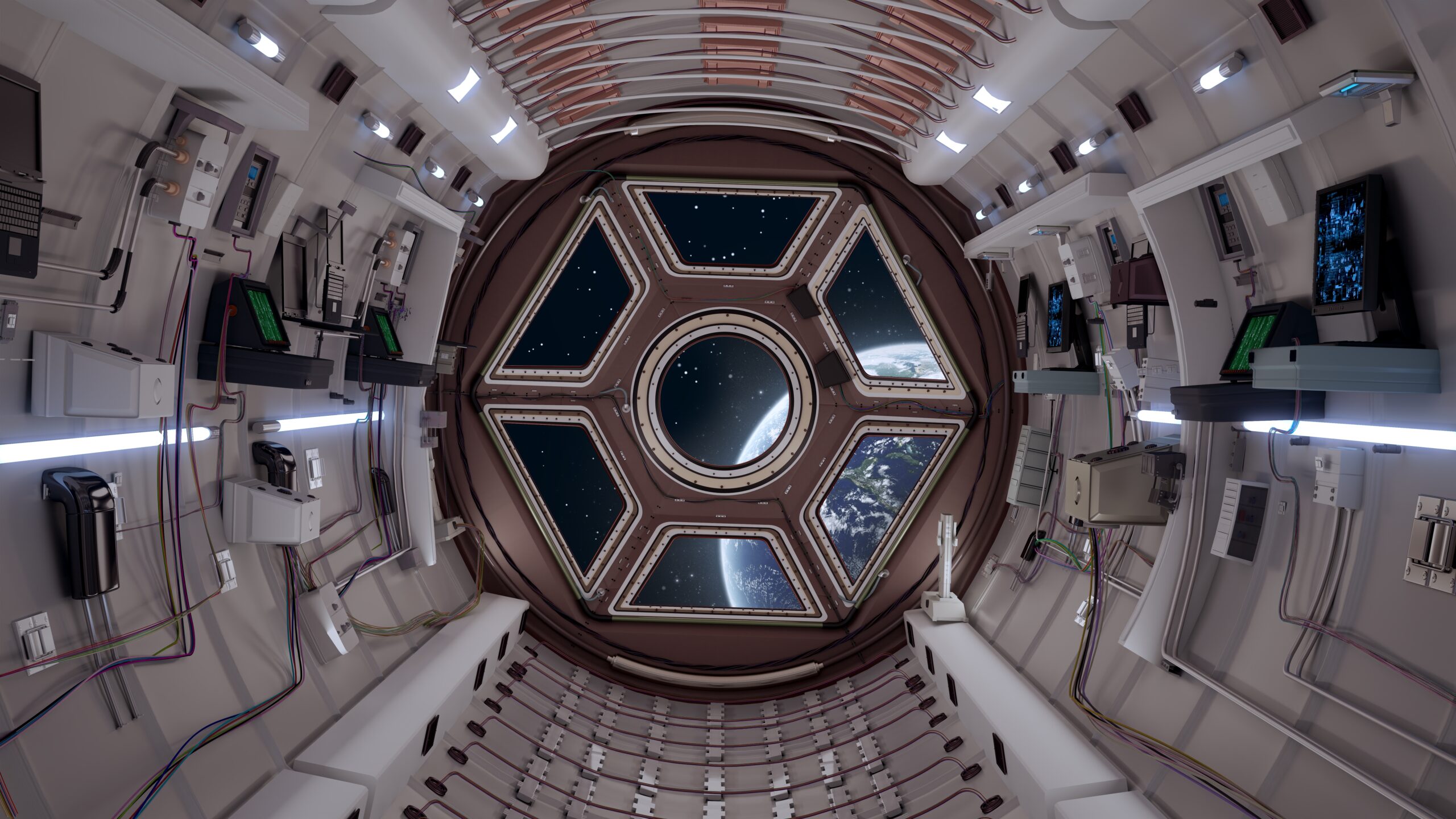

Alkegen’s CryoTherm®, Cryo-Lite®, and CRS Wrap® products insulate supercooled tanks and space systems—preventing rapid boil-off, supporting launch vehicles, and maximizing fuel efficiency in orbit. These materials provide ultra-low thermal conductivity solutions for cryogenic tanks (liquid hydrogen/oxygen), avionics, and long-duration space systems—crucial in both deep cold and rapid thermal cycling.

Applications

- Cryogenic Pipes on Launch Sites

- Cryogenic Tanks

Learn More

Alkegen’s CryoTherm®, Cryo-Lite®, and CRS Wrap® products insulate supercooled tanks and space systems—preventing rapid boil-off, supporting launch vehicles, and maximizing fuel efficiency in orbit. These materials provide ultra-low thermal conductivity solutions for cryogenic tanks (liquid hydrogen/oxygen), avionics, and long-duration space systems—crucial in both deep cold and rapid thermal cycling.

Applications

- Cryogenic Pipes on Launch Sites

- Cryogenic Tanks

ALKEGEN REFRACTORY SOLUTIONS

Thermbond Refractory Solutions for Launch Infrastructure

Our advanced thermal materials are specialized for ultra-durable, rapidly deployable protection on aerospace launch pads, flame trenches, and ground infrastructure. Engineered for high thermal shock resistance, fast installation, and erosion resistance, Thermbond® ensures launch support structures endure rocket plume exposure, repeated rapid heating/cooling, and corrosive byproducts without premature failure or frequent maintenance.

Applications

- Flame Trenches

- Launch Pads

Learn More

Our advanced thermal materials are specialized for ultra-durable, rapidly deployable protection on aerospace launch pads, flame trenches, and ground infrastructure. Engineered for high thermal shock resistance, fast installation, and erosion resistance, Thermbond® ensures launch support structures endure rocket plume exposure, repeated rapid heating/cooling, and corrosive byproducts without premature failure or frequent maintenance.

Applications

- Flame Trenches

- Launch Pads

ALKEGEN FILTRATION SOLUTIONS

Cabin Air Quality & Fluid System Integrity

To ensure air quality, LydAir® MG and Arioso® composites ensure every passenger breathes clean, sanitized air. Designed to minimize differential pressure and maximize service life amid recirculated flows. For liquid filtration, our LyPore® and Unity media protect mission-critical hydraulics and fuel, filtering out wear particles, water, and bacteria to safeguard engine performance and actuator reliability even in harsh, contaminated zones.

Applications

- Cabin Air Systems

- Hydraulics and Fuel Filtration

Learn More

To ensure air quality, LydAir® MG and Arioso® composites ensure every passenger breathes clean, sanitized air. Designed to minimize differential pressure and maximize service life amid recirculated flows. For liquid filtration, our LyPore® and Unity media protect mission-critical hydraulics and fuel, filtering out wear particles, water, and bacteria to safeguard engine performance and actuator reliability even in harsh, contaminated zones.

Applications

- Cabin Air Systems

- Hydraulics and Fuel Filtration

ALKEGEN BATTERY & FIRE PROTECTION SOLUTIONS

Advanced Battery & Fire Protection Technologies for Safety & Performance

Our thermally and electrically insulating FyreWrap® LiB and XPF solutions prevent hurtling flames, high-voltage arcing, and smoke in crewed vehicle batteries, cockpit modules, and satellite payloads. FyreWrap® LiB Performance Materials are next-generation flame barriers and electrical insulators that withstand >1,100 °C to halt battery thermal runaway in electric aerospace powertrains and satellite packs. Our FyreWrap® XPF Expanding Paper is an intumescent, flexible paper that expands under heat to seal gaps, blocking flame and smoke during fires in avionics, cargo, and cockpit enclosures.

Applications

- Aerospace Craft Battery Packs

- Cockpit

- Satellite Packs

Your Aerospace Partner

Compliance & Assurance

Materials designed to meet demanding aerospace standards and reduce regulatory risks.

Measured Operational Value

Lighter weight, longer service life, and proven reliability across missions.

Global Engineering & Support Ecosystem

AS9100-certified production with rapid prototyping and field-engineered solutions tailored to aircraft, spacecraft, and launch systems.

Thermal Resilience

Continuous protective performance above 1200–1600 °C (vehicle) and superior launch infrastructure lifespan.