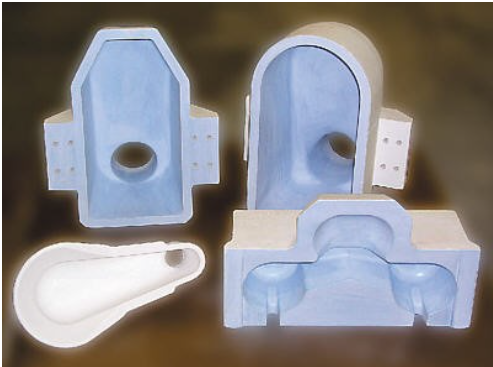

FUSiO2N™ SP pour basins provide long life and thermal insulation for your molten metal pouring needs. Rex Materials has developed a family of fused silica products. FUSiO2N SP was specifically developed for pour basin applications. Pour basins can be ordered with a special BN coating to make them non-wetting to aluminum and other metals. Long life, thermal shock resistance and thermal insulation are the key characteristics of FUSiO2N SP pour basins.

FUSiO2N SP Pour Basins can be manufactured to your exact specifications or our team of engineers can design one for you.

| Features | Benefits |

|---|---|

| Low Coefficient Of Thermal Expansion | Excellent Thermal Shock Resistance & Dimensional Stability |

| Low Thermal Mass & Conductivity | Thermal Insulation, Minimizes Temperature Loss |

| Chemical Inertness | Long Life, Corrosion Resistance |

| High Hardness | Long Life, Wear Resistance |

| Unique Cast Technology | Cost Effective, Complex Shape Capability |

FUSiO2N™ represents a family of high purity fused silica materials tailored to achieve optimum properties required for molten metal applications. FUSiO2N products are precision cast into a wide variety of sizes and shapes, from small and intricate to extremely large, including shapes with complex internal features – typically without the need for costly machining.

FUSiO2N is made from fused silica that has been sintered to a high temperature. Today they are used in many non-ferrous applications, including but not limited to, tap blocks, trough liners, filter bowls, flue port blocks, pour basins, spouts, control pins, and dipping ladles. Rex Materials’ ability to supply quality shapes cost-effectively enables you to use FUSiO2N parts in applications where ordinarily fused silica products have been too expensive.

FUSiO2N SP pour basins are made with a unique process allowing us to be very cost effective. FUSiO2N SP pour basins come in sizes up to four feet wide. Standard or custom designed pour basins are available.