PureFrax Hot Gas Filters by Alkegen

Combining over 125 years of ceramic fiber and filtration solutions

Purefrax® Purefrax® CC

Purefrax® CC Benefits

- Increased gas-catalyst contact versus traditional Selective Catalytic Reduction systems due to catalyst coated fiber matrix

- Physical barrier against catalyst poisons resulting from external wall cake filtration

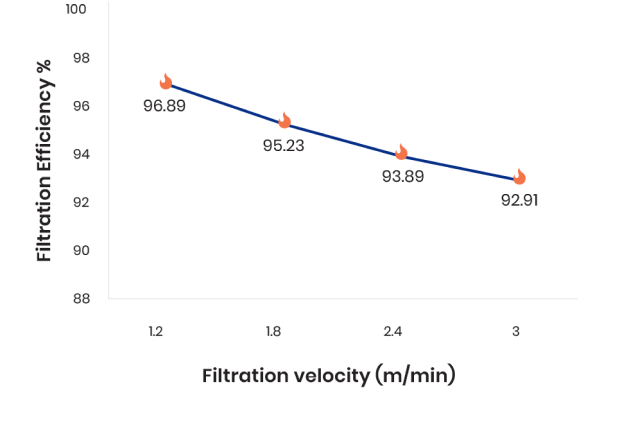

- High efficiency across the catalyst working temperature range

Industrial Filtration Has Never Been More Efficient

Trusted Partner for Many Applications Since 1996

With our thorough understanding of customer needs and expectations, we provide solutions that are suited to a range of industries.

Documents

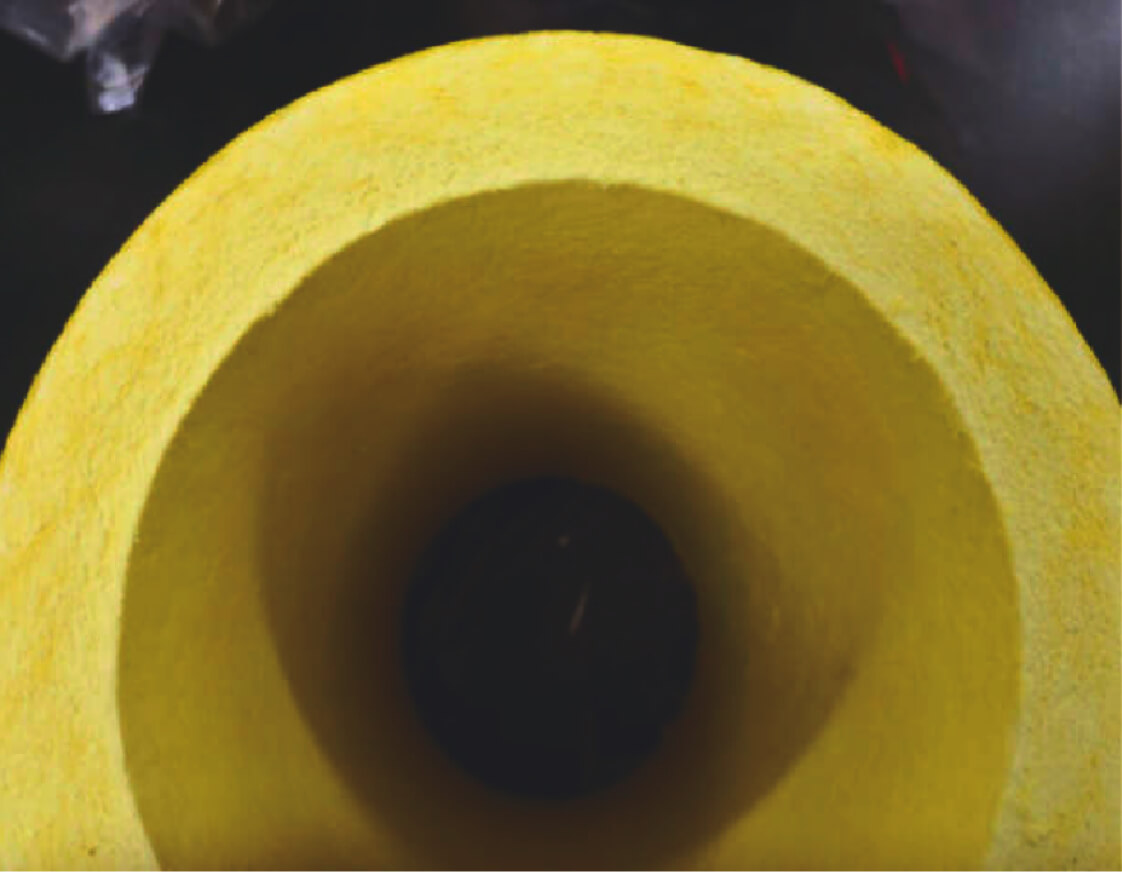

Purefrax® elements are available in 1m to 4m single piece lengths and are supplied with gaskets to ensure good sealing. Contact us to learn more.