Sealing

High Performance Sealing Solutions

An innovative portfolio of products for a wide range of applications in the automotive, heavy-duty diesel, small engines, industrial and related industries.

Who We Are

Interface Performance Materials by Alkegen is the leading manufacturer of sealing systems and engineered composite materials. For more than 100 years our advanced engineering expertise, global manufacturing excellence, innovative portfolio, and unique product validation capabilities allow us to be your strategic source for technically reliable gasket solutions. Our products include high performance materials utilized in heavy-duty diesel, automotive, small engine, industrial, and aligned Tiered-component manufacturing industries. Our extensive knowledge within these application spaces allows us to respond effectively to the ever-changing industry demands. This is framed via customized solutions that precisely fit the expectations for performance, reliability, and best overall value.

Technically Reliable Solutions

Our commitment to quality across all processes and all products consistently meets the quality standards of leading customer programs worldwide. Our design and validation processes include rigorous performance testing. Every material shipment is lab certified. Our highly experienced product and application engineers complete thousands of hours of functional testing, validating material performance and long-term durability. The result: robust solutions that optimize costs and satisfy the most stringent requirements.

Gasket Engineered Composite Materials

High performance sealing solutions for a range of applications in the automotive, heavy-duty diesel, small engines, industrial and related industries.

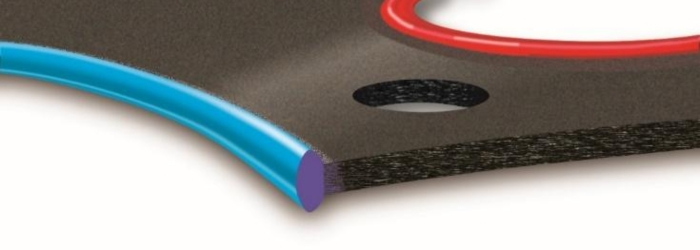

Select-A-Seal® Rubber-Edged Composite Gasket

Perimeter sealing technology that prevents moisture ingress and helps to eliminate corrosion migration where a reliable barrier is critical to operation.

Gasket Engineered Composite Materials

High performance sealing solutions for a range of applications in the automotive, heavy-duty diesel, small engines, industrial and related industries.

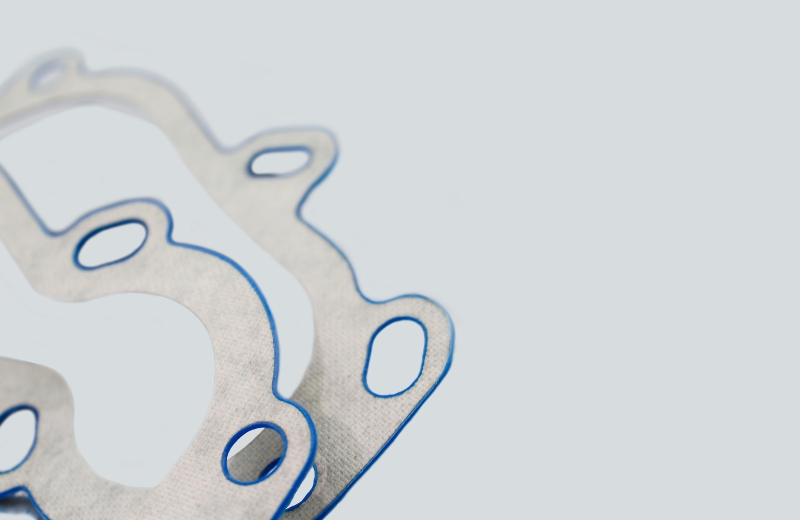

Select-A-Seal® Rubber-Edged Composite Gasket

Rubber-edged composite gasket that delivers dual-mode seals in one unique product

Select-A-Seal is the best-performing seal in its class – delivering dual-mode seals in one unique product. Consisting of an engineered composite material combined with an elastomeric rubber bead, Select-A-Seal delivers a precisely custom-engineered sealing solution for lubricants, oils, coolants, water and air in a wide variety of applications focused in the automotive, agriculture, electrification, heavy duty truck, drive modules, construction and earthmoving markets.

Benefits

- Cut lead times and increase speed to market with our rapid prototyping

- Save time and money with our predictive engineering capabilities including Finite Element Analysis

- Reduce manufacturing rework and field service repair time

- Resists and prevents flange corrosion

- Lower total assembly cost

- Increase customer satisfaction with best-in-class sealing performance and reliability

Applications

Select-A-Seal® rubber-edged composite gaskets can be used in a variety of applications including:

- Transmissions

- Axles

- Compressors

- Small engines

- Automotive engines

- Heavy duty diesel engines

- Hydraulic pumps/motors

- Steering systems

GEN2 Select-A-Seal® Rubber-Edged Composite Gasket

Perimeter Sealing Technology for Corrosion Mitigation

Adhesion + Compression = Superior Sealing Performance

Our composite sealing solutions for heavy duty agriculture and construction vehicles are engineered to stop corrosion from the perimeter of the application.

The innovative rubber edge prevents salt ingress, moisture, and contaminants from penetrating the barrier with protection that withstands environmental impact for up to 15 years.

Features and Benefits

- Warranty Performance

- Serviceability

- Lowest “load to seal” technology

- Environmentally Clean

- Corrosion Mitigation

- Prevalent in AL and Electric Drive Units

The Science Behind the Seal

GEN2 Select-A-Seal is engineered with Rubber Edge Construction (REC), a perimeter polymer edge specifically designed for demanding environmental applications.

Industry Challenges:

- Flanges will corrode due to saltwater exposure

- Traditional solutions including REM, RCM, Liquid, Foam and O-Rings can allow water migration.

Solution:

Perimeter Select-A-Seal polymer prevents moisture ingress and helps to eliminate corrosion migration.

Industrial Thermal Management Insulation

Millboard

Thermal Millboard for Refractory Applications

Interface millboards are 100% asbestos-free.

To meet the needs of the global iron and steel processing industries, and other industrial operations that require high-temperatures, Alkegen’s Interface Performance Materials offers three types of refractory millboard. 100% asbestos-free refractory materials are available for both continuous and “one shot” applications.

Millboard

Industrial Thermal Management Insulation.

412 Millboard Materials

412 millboard is a ceramic fiber board with inorganic fillers. It is an exceptional thermal insulator and is used for high temperature roll coverings and in fire protection areas where high strength properties are required. It is intended for applications with maximum continuous operating temperatures up to 1260°C (2300°F), and it resists melting up to 1760°C (3200°F).

1401 Millboard

1401 millboard is a high temperature material for use in gasketing, insulation, personal protection, heat and flame barriers, dryers, parting media and expansion joints. It is intended for use in applications with maximum continuous operating temperatures up to 1260°C (2300°F) and it resists melting up to 1760°C (3200°F).

RG30 Refractory

RG30 Millboard is manufactured with high purity ceramic fibers. It has the lowest shot content of our refractory millboard line. It is recommended for “one shot” applications such as casting process mold gaskets, for example, to 1482°C (2700°F).